What is the process for balancing a centrifugal compressor?

[ Follow Ups ] [ Post Followup ] [ Mens Message Forum ] [ FAQ ]

Posted by HollisFoday on November 08, 2024 at 15:15:31:

Watch YouTube Short

Methods to Reduce Vibration with Balanset-1A Rotor Balancing Device

When it comes to technical machinery, balancing is crucial for optimal performance. The Balanset-1A rotor balancing device ensures precise balancing, eliminating vibrations that can lead to equipment wear and inefficiency.

Before initiating the balancing process, it's essential to ensure that the machinery is in good working condition, with properly installed bearings and a clean rotor free from any contaminants that could interfere with the balancing procedure.

Prior to measurements, it is recommended to place and set up vibration and phase sensors according to the manufacturer's guidelines.

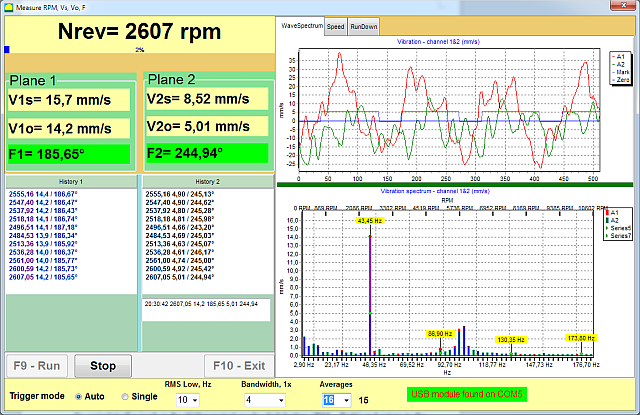

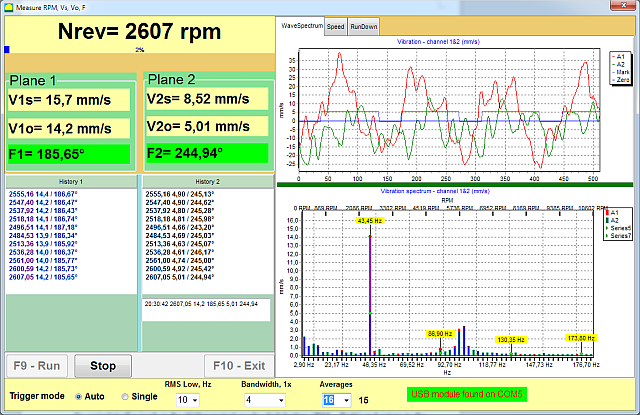

Utilizing a vibrometer for preliminary measurements can provide valuable insights into the vibration characteristics of the machinery. By analyzing the total vibration and rotational components, it becomes possible to identify the primary sources of imbalance within the rotor.

For effective balancing using the Balanset-1A device, it is advisable to address any significant static imbalance beforehand. This can be achieved by manually rotating the rotor by 90 degrees and adjusting counterweights to stabilize the rotor in various positions.

The Balanset-1A device offers a range of features that make it a versatile and user-friendly tool for balancing and vibration analysis:

- Compact and Portable: The device's compact design allows for easy transport, ideal for on-site work or field conditions.

- Intuitive Software: The device's software provides step-by-step instructions for setup and balancing, ensuring ease of use.

- Multi-functionality: Combining vibrometer and balancing functions, the device offers comprehensive vibration analysis and balancing capabilities.

- High Measurement Accuracy: With precision up to В±1В° for phase measurements and В±5% for vibration levels, the device meets high standards of accuracy.

- Customizable Options: The device includes features such as polar diagrams and ISO 1940 balancing tolerance calculations, allowing for tailored adjustments.

- User-Friendly Interface: The device is designed for easy operation, making it accessible to users with varying levels of expertise.

- Support for Serial Balancing: Ideal for repetitive balancing tasks, the device streamlines the process for efficiency.

- Cost-Effective: Balanset-1A provides a cost-efficient solution without compromising on quality, making it a valuable investment for improving product quality.

The Balanset-1A rotor balancing device from Vibromera simplifies the balancing process with its advanced features and user-friendly interface. By following the recommended procedures and utilizing the device's capabilities, operators can achieve optimal balance and reduce vibrations effectively.

For a comprehensive overview of the balancing process using the Balanset-1A device, refer to the detailed steps outlined by Vibromera:

- Equipment Preparation: Install vibration sensors perpendicular to the rotor's axis and set up the laser tachometer for rotational speed measurement.

- Initial Vibration Measurement: Determine the initial vibration level to assess the existing imbalance.

- Single-Plane Balancing: Place test weights in the first balancing plane and measure vibration levels.

- Two-Plane Balancing: Transfer test weights to the second balancing plane and conduct measurements for precise balancing.

- Imbalance Correction: Based on the collected data, the Balanset software will recommend corrective weights and installation angles.

- Final Balancing Check: Verify the balance by running the rotor and ensuring vibration levels are within acceptable limits.

By following these steps and leveraging the capabilities of the Balanset-1A rotor balancing device, operators can achieve optimal balance, reduce vibrations, and enhance the performance and longevity of their machinery.

[b]Contact Information:[/b]

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on eBay

Balanset-1A OEM on Etsy

Follow Ups:

Post a Followup

[ Follow Ups ] [ Post Followup ] [ Mens Message Forum ] [ FAQ ]